Four ways to speed up trains on the New Silk Road

The rail freight traffic between China and Europe is growing year by year. The logistics companies compete for every customer and every container. Therefore, they are constantly improving their service. What measures are they doing in order to speed up trains on New Silk Road?

Eventually, this route became a backbone of New Silk Road. As of today, there are several thousand trains a year running from China to Europe and back, while more and more countries join the transport corridor. The average train speed on the New Silk Road is 1,000 – 1,100 kilometres per day. This figure is a result of the numerous steps made by all the parties concerned. However, many difficulties and hitches occur when transporting containers on the New Silk Road, impacting the final delivery time of the shipment.

Forget about paper

Digitalisation is a trend in the rail sector, and the development has entered the New Silk Road too. Among the latest developments is the launch of the Xi’an-Hamburg multimodal service, via the port of Baltysk in the Kaliningrad Region of Russia. The notable feature of this connection is the single waybill for the entire route and for both modes of transportation, rail and ferry. The digital service was implemented by UTLC ERA.

Russian Railways, in its turn, has realised its own digital project known as Intertran. Freight operations are carried out much faster thanks to the use of electronic consignment notes. The project started in September 2019 when the first shipment from Yokohama to Moscow via Vladivostok was launched. This multimodal (sea-rail) connection was arranged by RZD and FESCO. During the first two months, over 300 containers were delivered from Yokohama to Moscow with the electronic consignments. According to RZD, the implementation of electronic documents has reduced the paperwork process by four days. And, of course, it allows the logistics providers to move the freight faster.

Text continues below the picture

Other transit countries on the New Silk Road are also implementing the electronic documents in their freight operations. Kazakhstan Railways has been testing electronic consignments in freight transportation between China and Kazakhstan, and it has successully implemented the digital product in the rail freight operations between Kazakhstan and Russia. In 2018, around 8,000 electronic consignment notes were issued in both directions: over 2,200 units from Kazakhstan to Russia and over 5,700 units back.

Belarusian Railway has introduced the electronic consignments for the transit of empty wagons from Russia to Latvia or Lithuania. Last year the railway company together with the State Customs Committee of Belarus started to examine the electronic documents on the route from Naushki, a border crossing between Russia and Mongolia, to Brest on the Belarusian-Polish border. Over 1,100 electronic waybills were issued in April – August 2018. Now, the parties are working on introducing the same solution for the opposite direction – from Brest to Naushki. Moreover, Belarusian Railway plans to implement paperless operations on the entire New Silk Road.

Bypass bottlenecks

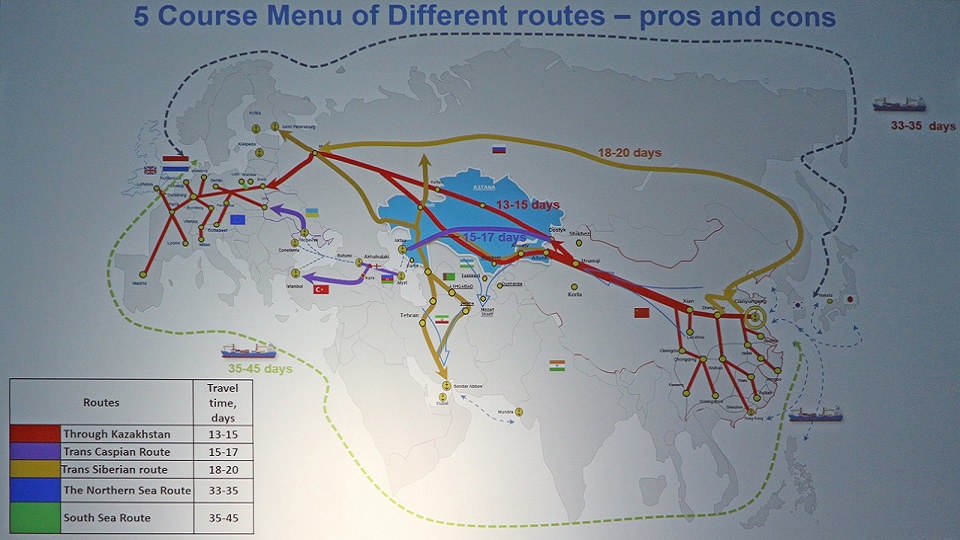

If you have no opportunity to improve the current railway line or construct a new one in order to avoid a bottleneck, you can bypass it by establishing a new route. That is what logistics companies do on the New Silk Road. Looking back at the history of the rail freight links between China and Europe, it can be said that a search of new routes is a permanent process. As we mentioned before, the first rail delivery on the New Silk Road was performed via Russia, Belarus and Poland. In a few years, the Kazakhstan route was introduced. Since 2017, container trains have been running from China to Europe via Mongolia.

The same process is going on in the European part of New Silk Road. Most of the container trains from China run via Duisburg, an important intermodal hub in Germany, and then they split into the numerous links across Europe. Now, the logistics providers try to establish more and more deliveries bypassing Duisburg in order to make the intermodal service faster and more reliable to the customers. This is particularly true for the Central and Southern European countries because the links via Duisburg mean a longer detour for them. Rail Cargo Group from Austria has succeeded in this area: the company launched several direct container trains from China to Central Europe without a stop in Duisburg.

Text continues below the picture

In the course of time, logistic companies have focused on multimodal solutions, which include both rail and sea services. In the mid-2010s Kazakhstan joined forces with Azerbaijan and Georgia for establishing the Trans-Caspian International Transport Route (now known as the Middle Corridor). Initially, this corridor connected China and the Caucasian region including a ferry leg across the Caspian Sea. Afterwards, Turkey, Ukraine, Romania and Poland joined the project. This resulted in a new ferry leg – now via the Black Sea. In 2015-2016, several pilot trains were launched: Shihezi (China) – Keshla (Baku, Azerbaijan), Lianyungang (China) – Istanbul (Turkey) and Chornomorsk (former Illichivsk in Ukraine) – Dostyk (Kazakhstan). Polish company PKP LHS also examined the route for freight transportation to China and Iran. In October 2019 the Middle Corridor got a new option for transit. The Marmaray Tunnel beneath the Bosphorus Strait became a part of the route: it simplified the delivery by eliminating the Black Sea leg.

The other multimodal corridor being actively used by Russian logistics companies runs via the Kaliningrad Region. UTLC ERA established this route in 2018. It has two options. The first one includes the use of the intermodal facilities situated in the region. They allow entering Poland from the northeast and bypass the congested Brest/Malaszewicze crossing on the Polish-Belarusian border. Meanwhile, a second option is offered by the shipping lines between the ports of the Kaliningrad Region (Kaliningrad, Baltiysk). Today, this route is followed for the connection from China to Rotterdam, Hamburg, Rostock and other European destinations

Invest in assets

Another way to speed up container trains from China to Europe is to improve the existing rail infrastructure and the network of intermodal facilities, as well as to upgrade rolling stock or purchase new material. In terms of rail infrastructure, Kazakhstan made significant progress in the last decade. At the dawn of the New Silk Road, there was only one railway border crossing between China and Kazakhstan, located in Dostyk. In 2016 a new border point with a high-capacity intermodal terminal was opened in Khorgos. Also, Kazakhstan constructed over 2,500 kilometres of new railway lines and upgraded 10,000 kilometres of the old one during the last ten years.

Text continues below the picture

Russia, in its turn, modernises the tracks of Trans-Siberian Railway, which is vital for the China-Europe trains. New border crossings were opened in Belarus in order to diversify the traffic to Poland. The latter also improves the infrastructure of Malaszewicze railway junction. In terms of rolling stock, many railway companies invest in new locomotives and flat wagons. For instance, PKP Cargo got 20 new multisystem locomotives. Inter alia, they haul container wagonsets from the Belarusian border to the German one.

Overcome the break of gauge

On the way from China to Europe, containers are reloaded once, twice or even more times. This is caused by the break of gauge across Eurasia: China and most of the EU Member States operate railway networks with a gauge of 1,435 millimetres, while Russia, Kazakhstan, Belarus and other former Soviet countries use broad gauge of 1,520 millimetres. A possible solution to reduce the number of switches could be the variable gauge system. Thus, Polish rail freight operator PKP Cargo plans to adopt the SUW2000 system for East-West rail services, including those from China. The technology allows the railway companies to run their trains on both, standard and broad, gauges without a bogie change.

SUW2000 was invented by the Polish engineer Ryszard Suwalski at the turn of the 1980s and 1990s. At the end of the 1990s, the system was installed by the Polish company ZNTK Poznań, at the stations of Mockava and Mostyska on the border with Lithuania and Ukraine. SUW2000 has been used for several years to speed up passenger trains from Warsaw to Vilnius and from Lviv to Wrocław (via Kraków). Now, the system is being used only on the Polish – Ukrainian border and for passenger trains solely.

Text continues below the picture

In September 2019, PKP Cargo purchased the patent for SUW2000 and declared its intention to use the solution for freight operations. “To use it commercially, you need to think about a train, not single wagons. Our container trains have 30-40 wagons. Transportation on the New Silk Road is very important to us and sensitive to the journey time – that is why this solution provides a good chance”, said Czesław Warsewicz, CEO of PKP Cargo. To implement this solution for rail freight, dedicated rolling stock with variable bogies is required. How the Polish rail freight operator plans to address the issue is currently unknown.

It is worth to add that similar technology is being successfully used by Russian Railways for passenger transportation for several years. To this end, the Spanish technology Talgo-RD has been installed by RZD at the Brest railway station in Belarus, where two different gauges are connected. In December 2016, the Moscow – Berlin train was launched, without bogie change. The Russian company still operates this technology for its international trains to Warsaw, Berlin, Paris and other European cities.

Want to know more?

At RailFreight.com New Silk Road traffic is one of the main topics we cover. If you want to make sure you do not miss out on the latest news about this theme, you can subscribe to our newsletter, or visit one of our events.

Read also:

- New Silk Road in 2019: more trains, less empties and lots of politics

- ‘East-West balance on New Silk Road can never be reached’

You just read one of our premium articles free of charge

Want full access? Take advantage of our exclusive offer