Is this Minecraft, or just the future of terminal operations?

Overseeing terminal operations to ensure efficient control and safety in real life is one thing. However, migrating a whole terminal and its operations in a digital 3D environment is completely revolutionising. For Minecraft enthusiasts, this might sound like a dream, but it is not. “Imagine a world where every container and cargo piece is not just a line item on a spreadsheet, but a vivid, tangible entity in 3D space,” says Dr. Péter Galambos, CTO and founder of MaxWhere. MaxWhere’s 3D digital twin concept can make this happen, and its implementation in state-of-the-art terminals stands as proof.

The importance of digitalisation within the rail freight industry has been overstressed, and for a good reason, since it can contribute significantly to improving operational efficiency. “Real-time cargo tracking, predictive maintenance, optimised route planning, and streamlined logistics can all contribute to reduced costs and increased profitability. Now it is time for the sector to start investing: a well-executed digitalisation strategy tailored to a company’s requirements can yield substantial long-term benefits,” explains Dr. Galambos.

Nevertheless, the 3D digital twin concept, as implemented by MaxWhere, takes digitalisation a step further by providing a more delicate solution. “This 3D clarity isn’t just about aesthetics—it’s about empowering swift comprehension, fostering impeccable decision-making across departments, and synchronising your teams,” underlines Dr. Galambos. This is how the technology works.

The 3D digital twin concept

The digital twin concept first took root in the early 2000s within the manufacturing industry. However, it swiftly expanded its reach to encompass various other sectors. This digital representation, often termed a ‘digital shadow’, of tangible devices and high-level processes facilitates the integration, testing, monitoring, and maintenance of actual assets.

Over the past decade, the application of digital twins has proliferated across numerous sectors, including automotive, oil and gas, and transport and logistics. Key advancements like 3D visualisation (AR/VR), the Internet of Things, and the ever-expanding computational power on desktop platforms and in the cloud are driving the adoption of this technology.

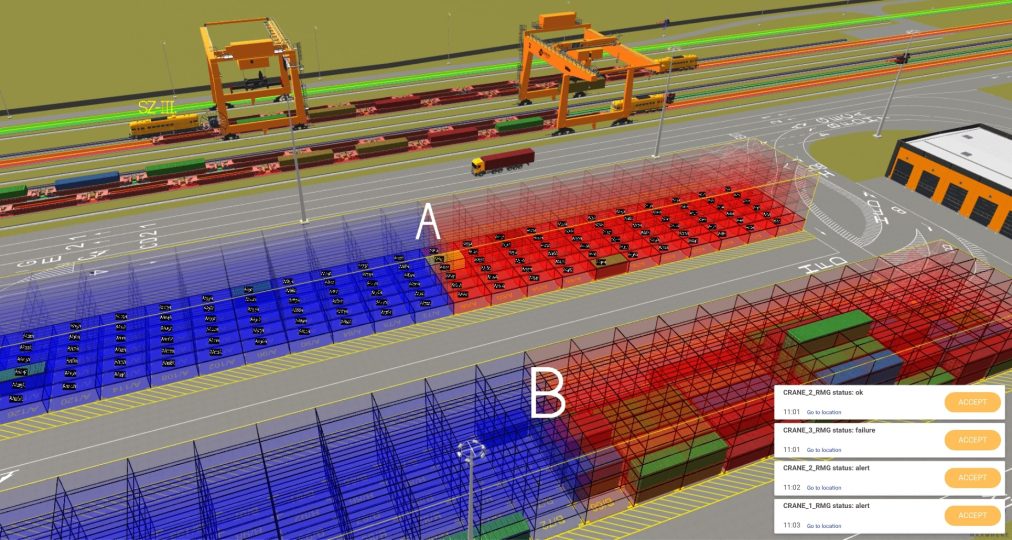

Real-time 3D digital replicas, a unique subset of digital twins, hold significant importance in managing expansive facilities such as container terminals and depots. These dynamic models facilitate instant and intuitive comprehension of the entire operation, eliminating the need to sift through intricate tables and lists.

How does it work?

Digital twins have advanced in tandem with other technologies that have evolved significantly over the past decade. At the heart of effective digital twins lie IoT tools. The surge in sensors, especially intelligent vision systems and interconnected devices, has facilitated real-time data collection from tangible objects and operations. Cloud-based or on-premises infrastructures deliver the essential computational strength and storage capacity to manage the vast data influx from sources such as gates, handling devices, cranes, and railway control systems.

MaxWhere’s strongest asset is the ability to harness this wealth of data, integrating it into a 3D layer to craft an immersive visual experience for both management and operators. The accuracy and timeliness of this data directly enhance the quality of the digital representation. Furthermore, MaxWhere offers the innovative feature of SmartBoards—2D screens situated within the 3D environment—that can exhibit any web-based content, be it operation-related documents, PDFs, photos, videos, or web applications. This streamlined access to work documentation augments user efficiency within the digital twin environment.

When asked what makes MaxWhere’s solution stand out, Dr. Galambos highlighted that “it is not just about visualisation; it is about revolutionising the realm of rail freight”. From pinpointing the real-time location of cranes, trains, and trucks to integrating live camera feeds and vital security features, we ensure operators are perpetually in the loop while ensuring seamless compatibility with your pre-existing systems, he adds.

East-West Gate leads the way

The tangible results of MaxWhere’s solution can be witnessed in one of Europe’s most modern terminals: the East-West Gate Terminal in Hungary. The 3D digital twin solution has been practically and successfully implemented in 2023, thanks to EWG’s management. “The company wanted to create an advanced terminal that harnesses new technologies like the campus 5G network, industrial IoT, and a digital twin-based operations centre,” says Dr. Galambos.

“MaxWhere embraced the opportunity and became an agile software vendor partner to EWG. Digital twin advancements were seamlessly integrated alongside the physical work throughout the construction process. By the time the last screws and bolts were secured on-site, the operations centre was already in full swing, facilitating the training of new staff members,” Dr. Galambos explains vividly.

However, this was only the beginning for MaxWhere, which is already working on the next major project. “We are actively delivering a project for the KTL Kombi-Terminal in Germany, a rail/road terminal close to BASF’s chemical park in Ludwigshafen. This proves that MaxWhere is not a mere concept or idea—but a tested and trusted solution by industry players,” concludes Dr. Galambos.