UK requires brake checks after Wales derailment and fire

Look again at the maintenance arrangements for wagons that primarily carry dangerous goods. That is the word from the Rail Accident Investigation Branch, the independent watchdog for safe operation of the railway network in the UK. The RAIB has ordered an urgent review of procedures, in the light of a serious derailment last summer, which saw an oil train with defective brakes come off the tracks in South Wales, resulting in a huge fire, significant infrastructure damage and a disastrous environmental incident.

The RAIB has said that responsible parties – officially Entities in Charge of Maintenance (ECMs) should review their system of inspection and maintenance for wagons that primarily carry dangerous goods, to ensure that they have appropriate arrangements in place to manage the safety risk associated with malfunction of the braking system.

Five point plan

The derailment and subsequent fire required the evacuation of hundreds of nearby residents. Although the significant spillage of oil cargo caused widespread damage to an environmentally sensitive area, and resulted in an intense fire that burned for several days, there were no injuries. However, lines and services were disrupted with a prolonged period of recovery.

In an effort to avoid a similar incident in future, the RAIB has issued an interim instruction, saying that designated Entities in Charge of Maintenance need to review their procedures and make assessments of their readiness. The safety body says they need to check five points specifically:

- They should asses the adequacy of facilities, tools and equipment at all maintenance locations

- Examine their systems for assuring the competence of those involved

- management systems and instructions for assuring the quality of work undertaken

- Look again at their methods for initial and ongoing assurance of the security of fastenings

- Go over their processes for the identification and tracking of safety critical components

All these assessment points, say the RAIB, should take into account the particular hazards associated with conveying dangerous goods.

Summer derailment in Wales

On the evening of 26 August this year, train number 6A11, a bulk freight service, departed on time at 21:52 from the Robeston (Milford Haven) oil processing facility on the south west Wales coast. The regular service was bound for Theale, a storage facility in Berkshire, near Reading, conveyed 25 tank wagons, each containing up over 75 tonnes of diesel or gas oil.

Shortly before midnight, at about 23:15, the train derailed on the near Llangennech, an outlying community of the larger town of Llanelli in Carmarthenshire. The derailment and the damage to the wagons resulted in a significant spillage of fuel and a major fire. Subsequent examination of the site revealed that a total of 10 wagons (positioned three to twelve in the train) had derailed. Around 330,000 litres of fuel had been spilt, much of it leaking into the environmentally fragile Loughor Basin, in what experts called an environmental disaster for the area.

Causes identified

The preliminary examination by the RAIB found that, although all the wheels of the train were probably rotating freely when the train left Robeston, at some point during the journey the brakes on all wheels of the third wagon of the train had become applied, and remained so until the derailment. Although their brakes were dragging, three of the four axles of this wagon continued to turn.

At some point in the journey the leading axle ceased to rotate altogether, as evidenced by a CCTV camera located at Pen-y-Bedd level crossing 12 miles (19 km) from the scene of the accident at Morlais Junction, and from identifiable damage to the railhead from that point onwards.

Accident became inevitable

The locking of the leading axle of the third wagon caused the development of a flat spot around 230 mm long on both of the wheels on this axle. This in turn created substantial ‘false flanges’ – raised lips on the outer side of the wheel treads. When the train reached the crossover at Morlais Junction, travelling at about 30 mph (48 km/h), the false flange on the right-hand wheel caught on the converging stock rail and distorted the track, leading to derailment of both wheels.

Around 100 metres further on, the partly derailed wagon encountered facing points set to route the train to the right. The locomotive and the two leading wagons went to the right and the derailed third wagon went straight ahead. The third wagon turned over onto its right-hand side and became detached from the wagon in front of it. This caused the points and the track beyond them to be destroyed, and derailment of another nine wagons followed.

Technical details

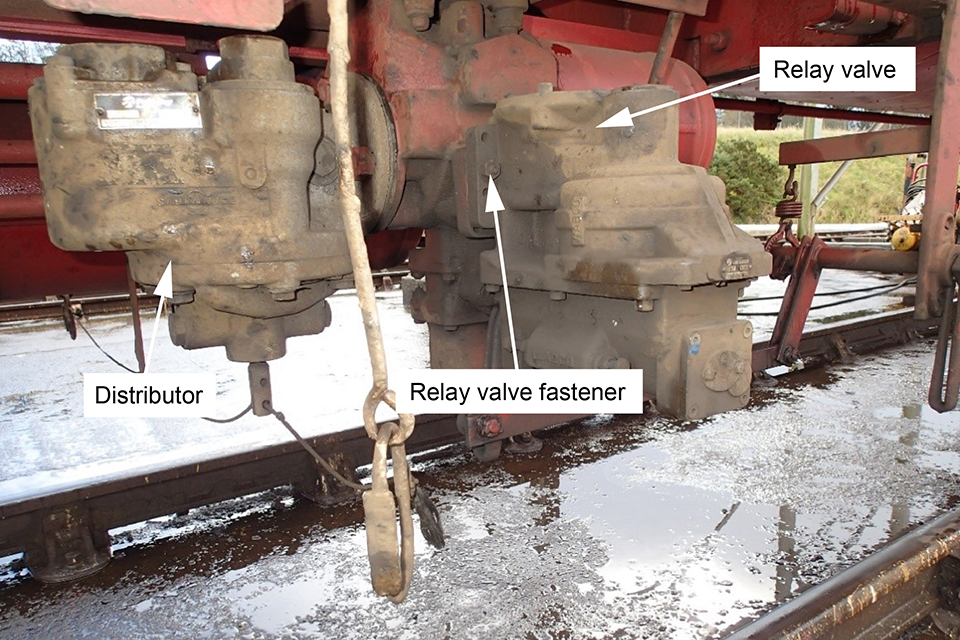

Examination of the brake group on the third wagon found that the relay valve was loose on the pipe bracket. A sealing ring from one of the ports in the mating face had migrated to a position where it lodged between two other ports, distorted the sealing rings of those ports, and probably created a route for air to pass directly from the auxiliary reservoir to the wagon brake cylinder. This would have had the effect of applying the brakes on the wagon, condemning it to the inevitable.

The RAIB say that in interviews later, the maintainer for the wagon was unable to identify with any degree of certainty where and when the fastenings of the relay valve had last been disturbed. RAIB suggest this may have taken place during routine repairs in the sidings at Robeston terminal or during scheduled maintenance elsewhere. Their interim report says there was no record of any check on the tightness of the fastenings ever having been made, and no process requiring such checks or provision of any measures, such as witness markings, which would have indicated that fastenings were becoming loose. In the light of these findings, they have issued their five point plan.

Action taken now and historically

Safety orders are often issued by the RAIB in the light of accidents. There is an established culture of review in the UK, which authorities claim makes the UK network among the most safety conscious in the world. Historically, far more serous incidents have resulted in widespread reform of network operations. Most recently, the fatal passenger train derailment at Stonehaven in Scotland, caused by a landslip, prompted a review of earthworks across the entire network. Twenty years ago, another fatal accident, this time at Hatfield north of London, resulted in a huge review of track maintenance which ultimately borough about the entire overhaul of infrastructure maintenance in the UK.

Network Rail say that the line in question – the Heart of Wales – which was destroyed in the accident will not reopen until the new year. The infrastructure agency was already engaged in repairs to the route, which was washed away at several other, more remote locations during a series of severe summer storms.

You just read one of our premium articles free of charge

Want full access? Take advantage of our exclusive offer

Is this evidence that thorough record keeping and process auditing is fundamentally important to these processes?